Product List

Client Case

Efficiency Verification of Cashew Shelling Machines

1. Place of Verification:Ghana

2. Company Name: Mim Cashew & Agricultural Products Ltd. ("Mim”)

3. Company Profile: Mim is a Ghanaian-based cashew nut producer invested by the Danish government. In 2015, it produced 3,000tons of cashew nuts. It is equipped with 150 manual shelling machines, 60 semi-automatic shelling machines, 70 mechanical extrusion type shelling machine and 30 prototypes of fully automatic shelling machine. Besides, it has purchased 20 sets of fully automatic shelling equipment. Mim also owns shelling machines used widely in the market. It has all kinds of shelling machines available in the market, providing a good premise for the verification.

4. Duration of Verification: March, 2015 (prototype of SS01 automatic shelling machine was sent to Mim) - November, 2015. We tested the semi-automatic, mechanical extrusion type and SS01 automatic shelling machine 24 hours a day in these eight months, and we got highly reliable data about the performance of these machines.

5. Data and Results of Verification: we have compared the performance of different kinds of shelling machines, and we got the following data and results:

Comparison of Shelling Results

|

Item |

Semi-automatic Shelling |

Mechanically-operated

Shelling |

SS01 Automatic Shelling |

|

Capacity (kgs/h) |

12 |

35 |

15 |

|

Shelling Rate (%) |

95 |

60 |

98 |

|

Rate of Unbroken Kernels (%) |

90 |

50 |

96 |

|

Labor (per set of machine) |

1-2 |

1

(maintenance personnel required) |

0 |

Appendix:

R&D, verification and delivery records of SS01 automatic shelling machine:

1) In December 2013, we launched the project to research and develop fully automatic cashew shelling machine

2) In April 2014, the design of drawings and principles of SS01 shell machine was completed

3) In June 2014, the first prototype of SS01 was assembled

4) In June - August, 2014, the commissioning of SS01 prototype was finished, and the second prototype was manufactured

5) In December 2014, the modified prototype of SS01 was completed

6) In January 2015, three prototypes of SS01 was shipped to Mim inGhana

7) In March 2015, three prototypes of SS01 arrived at the factory of Mim, and 24-hour-a-day test of these machines started

8) In November 2015, after 8 months of testing, these three prototypes were proved to completely comply with the shelling demands of Mim

9) In early November in 2015, Mim purchased 20 sets of SS01 automatic shelling machines

10) At the end of November, 2015, 20 sets of SS01 were shipped to Mim

11) In early February, 2016, Mim ordered 40 sets of SS01, which is expected to be shipped in April

SS01 has just started its journey of leading the global technological change of cashew processing practice!

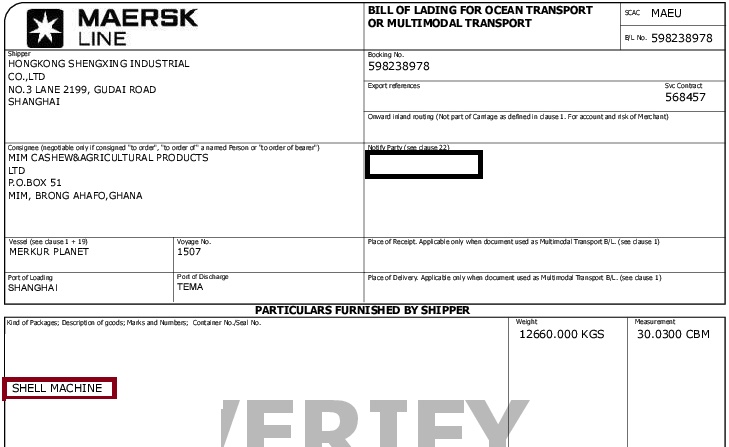

Pictures of Shipment and Bill of Lading of SS01 Fully Automatic Cashew Shelling Machine:

In June 2014,

SS06 automatic cashew (cashew nuts) dryer was delivered to Mim’s factory, and it works well up till now.In June 2014,

SS10 cashew (cashew nuts and kernels) separator was delivered to Mim’s factory, and it works well up till now.In March 2015,

SS07 automatic cashew nut dryer was delivered to Mim’s factory, and it works well up till now.Related Products

English

English